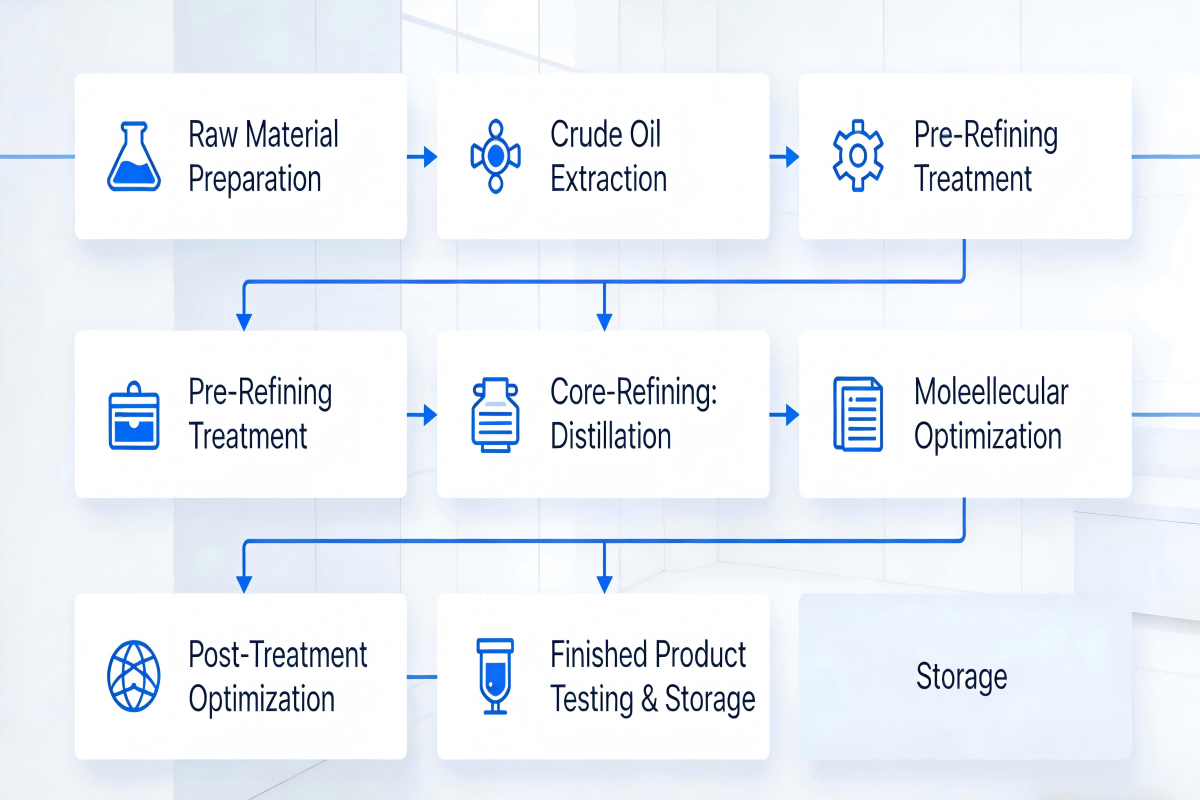

Raw Material Selection: Deep-sea fish rich in Omega-3 (EPA/DHA) (such as sardines, mackerel, salmon, anchovies) or fish processing by-products (fish heads, viscera, fish skin, etc.) are preferred.

Preservation Treatment: Raw materials require rapid low-temperature storage or direct processing to prevent oil oxidation and rancidity.

Washing and Crushing: After removing impurities, the raw materials are chopped or ground into a slurry to increase oil release efficiency.

2. Oil Extraction

Cooking and Separation:

The fish slurry is heated with indirect steam (usually 85–95℃) to denature proteins and rupture cells, releasing oil.

Crude fish oil, aqueous phase, and solid residue (fishmeal raw material) are separated by centrifugation or pressing.

Solvent Extraction (Partially Used):

For raw materials with low oil content, food-grade solvents (such as hexane) can be used to further extract residual oil, followed by solvent recovery.

3. Crude Oil Refining (Multi-stage Purification)

Degumming: Removes phospholipids and other gums; adds hot water or acid (e.g., phosphoric acid) and centrifuges.

Deacidification: Neutralizes free fatty acids with alkali (e.g., sodium hydroxide); removes soapstock by centrifugation, reducing acid value.

Decolorization: Adds activated clay or activated carbon to adsorb pigments, oxidation products, and residual impurities, improving oil color.

Deodorization: Passes steam under high vacuum (≤1 mbar) and high temperature (180–220℃) to remove volatile odor substances (e.g., aldehydes, ketones).

Wintering (Dewaxing): Low-temperature cooling (0–5℃) crystallizes high-melting-point saturated fats and waxes; filtration improves low-temperature transparency of the fish oil.

4. Concentration and Modification

Molecular Distillation/Supercritical Extraction:

Separates EPA/DHA from other components through high-vacuum short-path distillation to obtain high-concentration Omega-3 products (e.g., triglyceride type, ethyl ester type).

Ethyl ester fish oil can be enzymatically re-esterified into a more easily absorbed triglyceride form.

Antioxidant Treatment: Added natural antioxidants (such as Vitamin E and rosemary extract) to prevent oxidation.

5. Quality Testing and Standardization

Physicochemical Indicators: Testing for acid value, peroxide value, anisidine value, heavy metals (mercury, lead, etc.), polychlorinated biphenyls (PCBs), dioxins, and other contaminants.

Active Component Analysis: Determination of EPA/DHA content using gas chromatography (GC) or high-performance liquid chromatography (HPLC).

Standardized Formulation: Adjusting Omega-3 concentration and adding nutrients such as Vitamin D according to product requirements.

6. Packaging and Storage

Nitrogen-Filled Packaging: Using opaque capsules or dark bottles, filled with nitrogen to isolate oxygen and prevent oxidation.

Low-Temperature and Light-Proof Storage: Temperature and humidity are controlled throughout the process to maintain stability.

Key Technologies and Quality Control

Pollution Control: Modern refining technologies can significantly reduce heavy metals and persistent organic pollutants (POPs) to international standards (such as GOED, EPAX, CRN).

Full Traceability: From raw material origin to finished product, compliance with HACCP, GMP, and marine sustainability certifications (such as MSC, IFOS) is required.

Sustainability: Utilizing fishery by-products (such as fish liver, processing waste) to improve resource utilization.

Finished Product Types

Regular Fish Oil: Refined natural triglyceride oil.

Concentrated Fish Oil: Ethyl ester or re-esterified triglyceride type with Omega-3 concentration increased to 50–90%.

Pharmaceutical Grade Fish Oil: Requires higher purity and stability; used in prescription drugs or high-dose supplements.